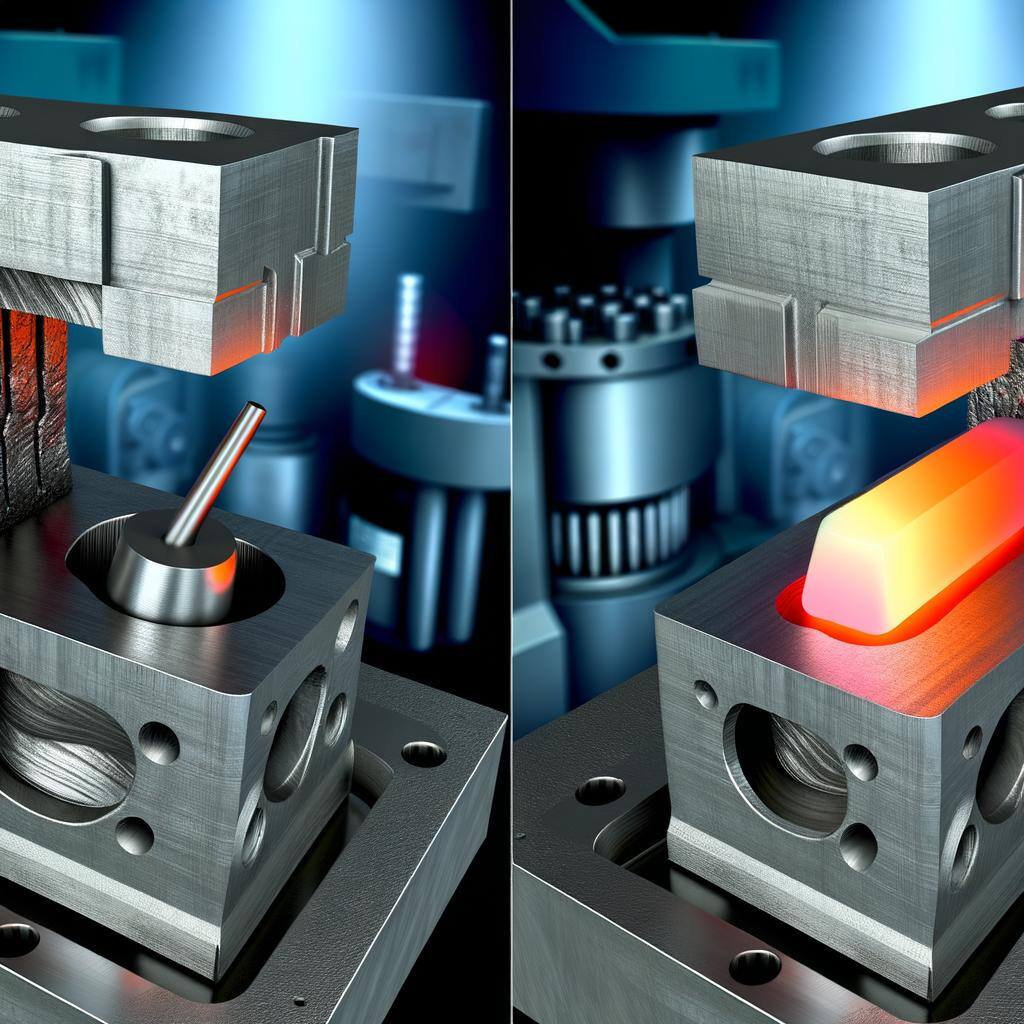

Premature tool failure is costly, wasting both time and money. Plus, the problems that lead to premature tool failure can also result in less accurate parts, longer process times, or wasted material and energy.

With forging simulation software, engineers can analyze the forging tools, parts being processed, and the forging process itself to optimize parameters well before any premature failures occur.

The Impact of Premature Tool Failure on Productivity

Processing materials in the solid state via plastic deformation typically requires a great deal of force. These tools are expected to be able to apply this force repeatedly for long periods.

Over time, a forging tool will wear down in certain areas, reducing tolerances and thus lowering the quality of the finished part. Premature tool failure can significantly impact productivity by reducing the speed of processes, causing delays in delivery to customers, as well as leading to higher operational costs. Beyond its financial implications, premature tool failure can also lead to disruption on the shop floor, resulting in lowered morale for employees.

Common Premature Failures That Shrink Margins

Every passing minute of non-operational tools can mean extensive losses, leading to decreased production cycles and lower sales revenue. With the right attention to detail in forging processes, you can avoid premature tool wear and keep margins healthy.

Performing a root cause analysis on premature forging tool failure requires significant time, energy, and resources from engineers. This often delays their ability to complete other pressing tasks related to operating or improving the forging process, creating a hindrance for many engineering teams. This substantial pause in productivity can diminish the effectiveness of an entire manufacturing operation if not managed efficiently by working with all stakeholders involved.

Common premature failures that result in squeezed margins:

- Broken dies

- Inaccurate dies

- Excessive post-processing on parts

- Spalling and accelerated wear out

- Abrasive wear to out-of-tolerance conditions

- Deformation of dies

Forging Simulation Software Keeps Tools Working Longer

Keeping tools working longer reduces downtime and saves money and time for the entire forge. While preventing premature tool failures used to only be available in the form of wisdom and experience from decades of experience, modern forging simulation software helps transfer those learnings to less experienced engineering teams.

Forging simulation software models the parameters and components used in the forging process. By being able to model forging tools, materials being processed, part designs, and the associated interactions, forging simulation software can accurately predict how the tools and parts will respond. The software analyzes the forces and stresses generated in the parts and tools while also highlighting potential issues that may occur in the tools over time. Some of the most important outcomes of forging simulation software are:

- Die stress analysis

- Tensile or compressive stress predictions

- Thermal steady state analysis

- Forging tool wear model

- Optimization linked with CAD for editing new optimized designs for the dies

Premature failures on the shop floor leads to wasted resources. When premature failures occur during simulation, engineers can change the tool, the part, or the forging process well before any damage occurs. By instantly visualizing the effects of edits, users can more concretely assess their progress and discern what works best in real-time.

Case Study: Cold Swagging Process Optimization with Forging Simulation Software

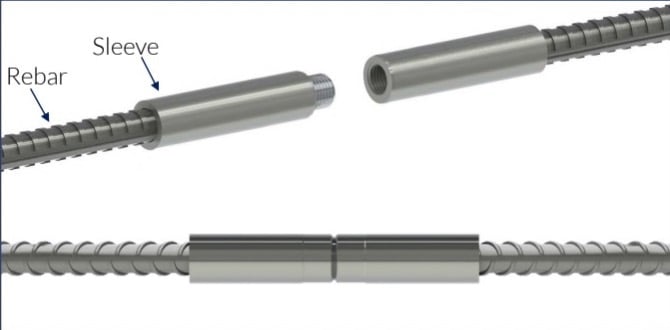

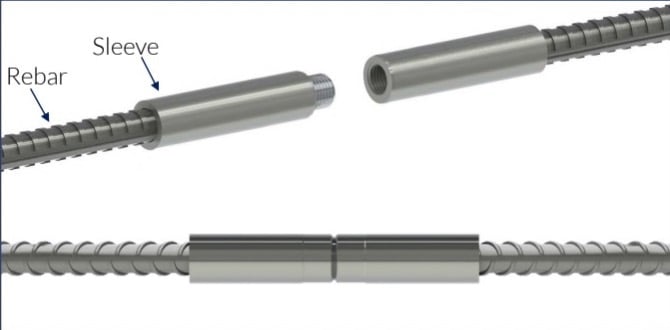

Dextra Group is a manufacturing, freight forwarding, and trading company specializing in supplying the construction and industrial sectors. Dextra produces a key component for the construction industry called Griptec®.

An important product for the nuclear industry, Griptec® consists of a sleeve that is swaged directly onto a length of rebar and then proof-tested by a non-destructive tensile test systematically performed by the swaging machine. Optimizing this process would help improve one of Dextra Group’s most competitive products.

Fig. 1 Griptec®, rebar slicing system by Dextra

The Problem

Dextra sought to optimize the forging process while ensuring exceptional product quality for one of their flagship products, Griptec®. Because Griptec® is so well trusted in the nuclear construction industry, any improvements to the production process had to result in the same or improved quality of the finished product.

Some of the key areas Dextra hoped to improve were:

- Improved swaging machine dimensioning by forecasting the loads applied to its tools

- Optimize the process by calibrating the load exerted by a resisting die

- Carry out parametric studies to determine the best die shape

- Determine the impact of various reinforcing bars geometries

The Solution

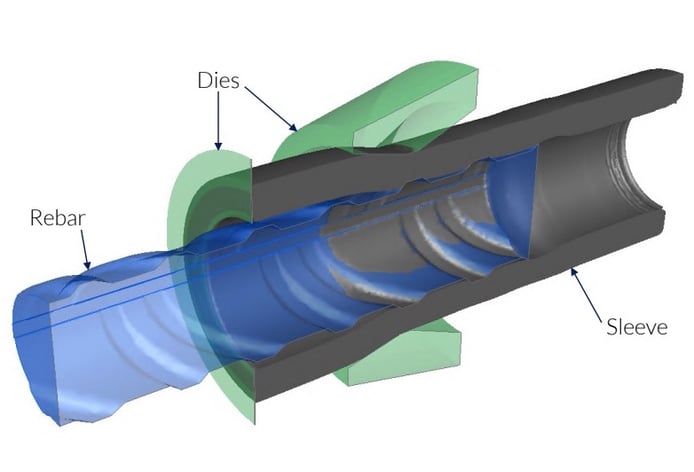

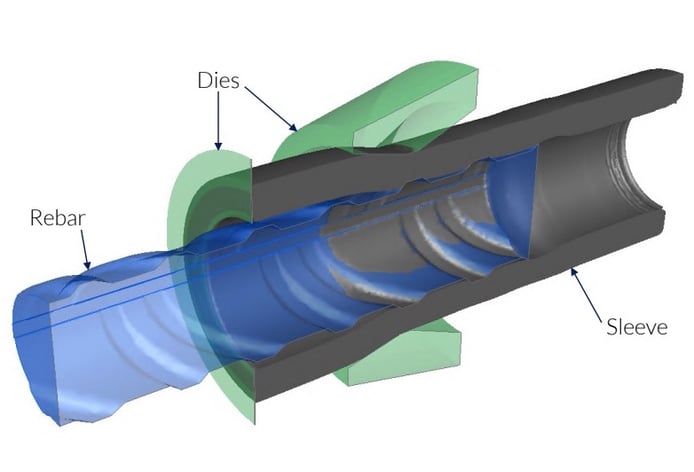

Using FORGE® simulation software, the Dextra team was able to model the forging process in a digital environment. Transvalor partnered with the Dextra team in properly meshing the models, applying boundary conditions, and defining the proper elastoplastic laws of material. With a properly tuned forging simulation, the Dextra team could begin optimizing.

With FORGE®, the Dextra team could model the evolution of the applied load throughout the swaging process. Understanding how these load changes allowed Dextra to improve how they dimension the hydraulic cylinders used to make Griptec®.

Fig 2. FEM simulation of a Griptec® extrusion

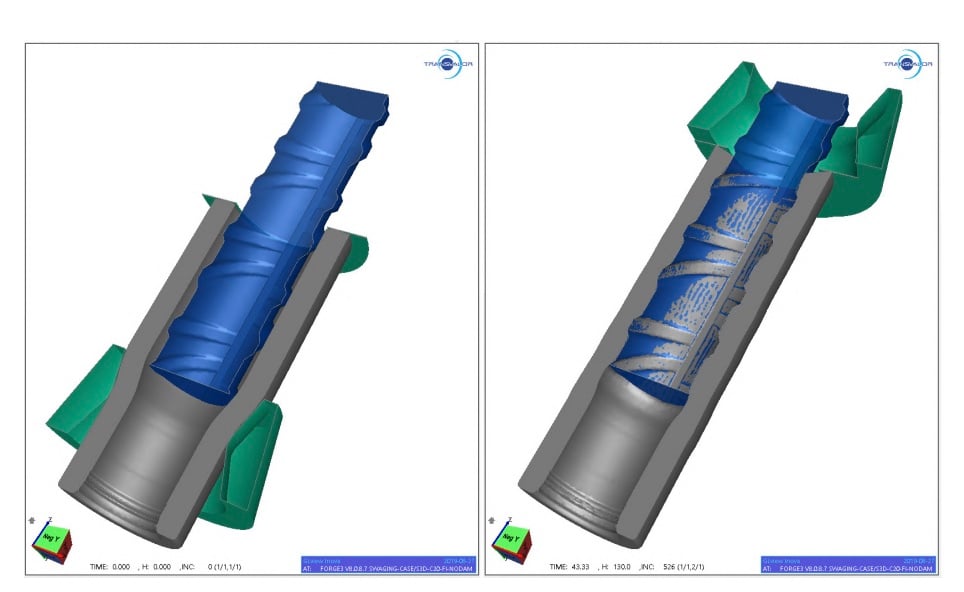

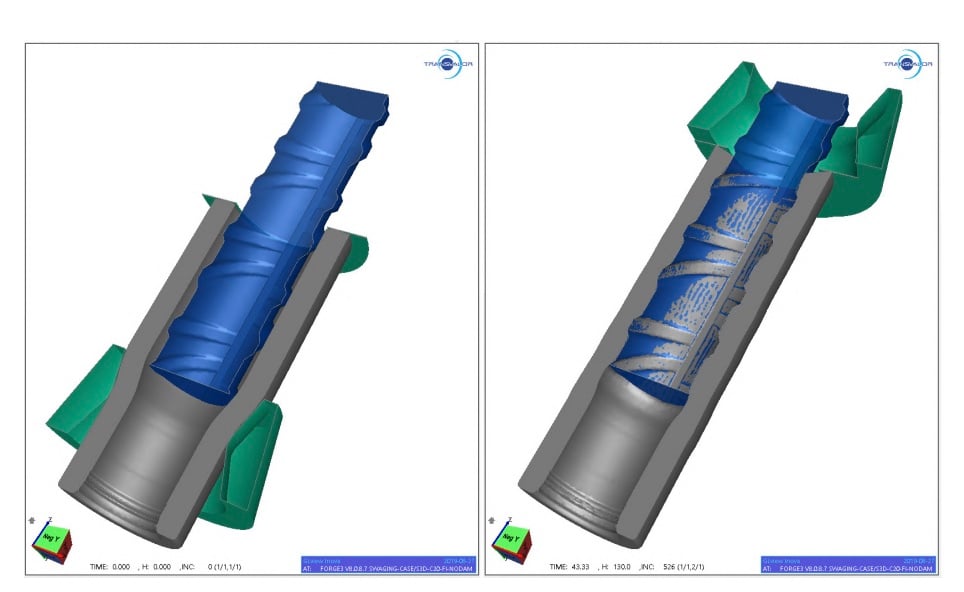

In addition to this load evolution, the forging simulation software provided a parametric study of the tools used in the process. New tool shapes and dimensions were generated that allowed the load applied to the tool to be reduced, extending tool life. In the parametric analysis, some parameters tested include:

- Swaging die diameters and angles

- Sleeve raw material and geometries

- Rebar geometries

Fig 3. Simulation of the swaging process of a Griptec® with FORGE® software

All of these learnings translated into actionable improvements Dextra could take to improve its forging process. By partnering with Transvalor, the engineering team was able to upgrade one of Dextra's cornerstone products.

Which Forging Simulation Software is Right for You?

In today's digital age, simulation software has transformed the forging industry. With optimized and streamlined operations, forges can remain competitive while effectively reducing costs and improving time management. When analyzing forging simulation software options, keep the following parameters in mind:

- Technical capabilities should meet the manufacturing needs

- Onboarding and training should be efficient

- Software should be easy to use

- Software maintenance and updates should be clearly defined

- Any additional hardware and/or equipment needed to integrate the software should be clearly understood

- Multiple case studies showcasing software capabilities should be available

Understanding how to compare different forging simulation software packages gives engineers an advantage in finding the one that will fit their forge the best. Staying competitive requires making changes, and forging simulation software is a great step to increasing efficiencies and reducing costs.

.png?width=500&height=70&name=Logo_Transvalor_2024_LD%20(2).png)